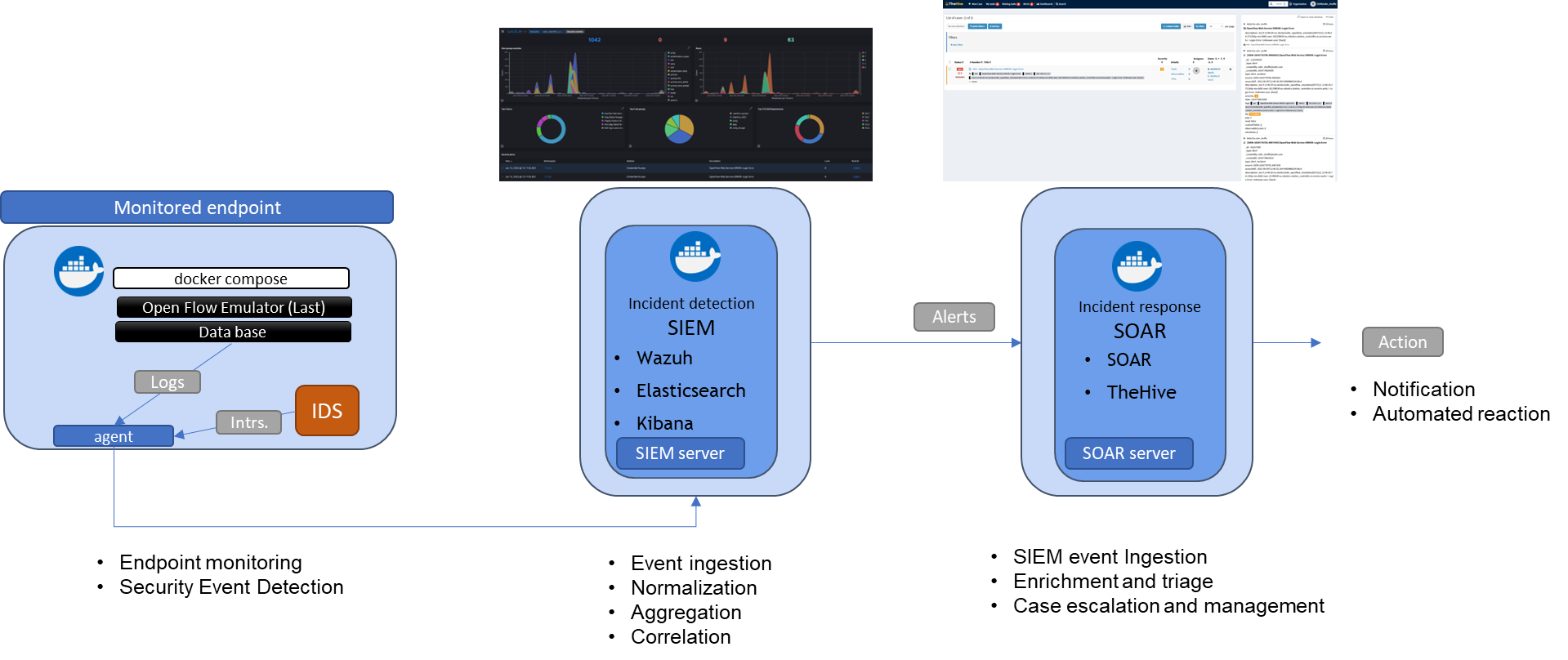

Prototype for a tailor-made cybersecurity solution, including the process and methodology for threat modelling and a cybersecurity toolkit with two main modules for incident detection and incident response.

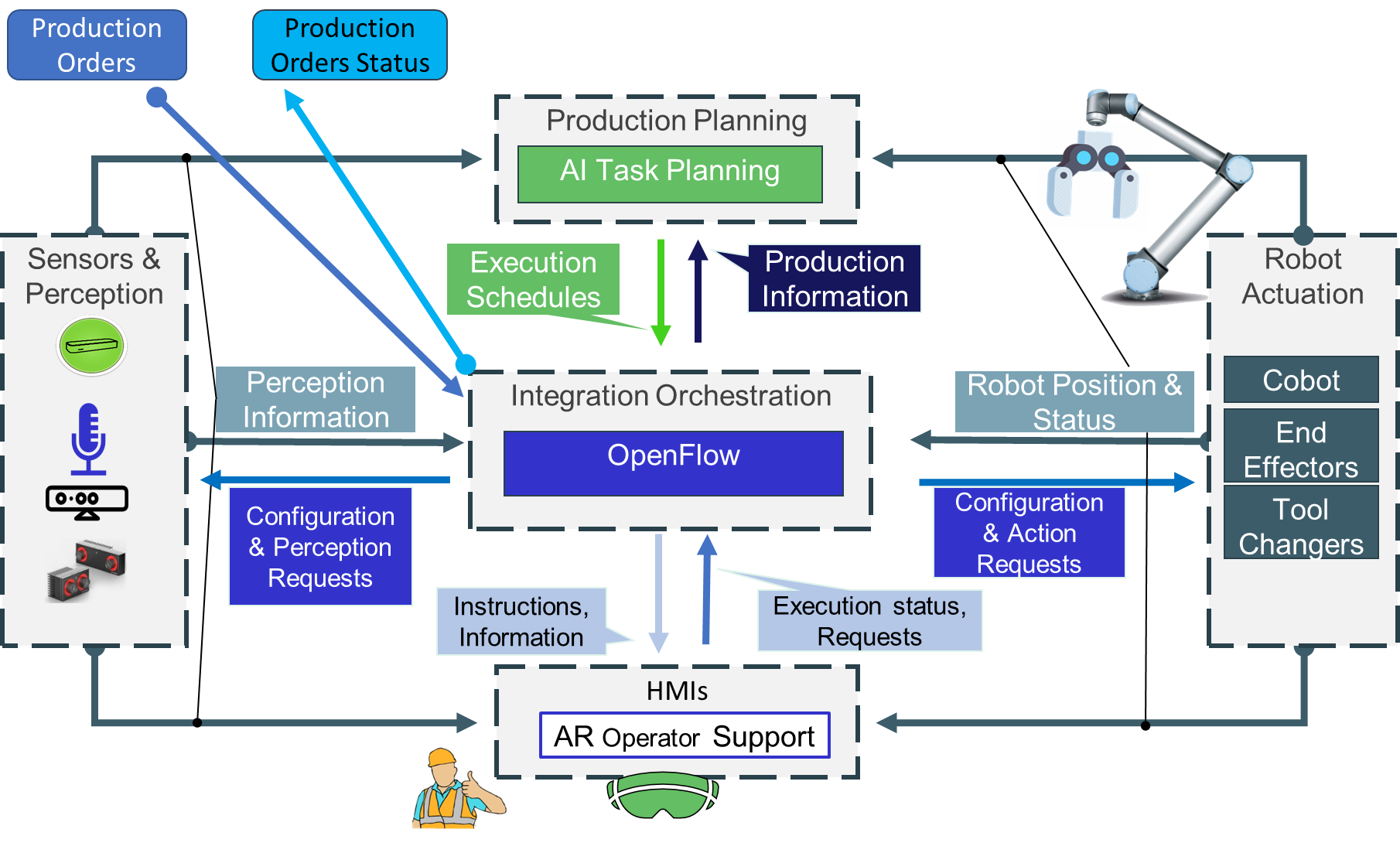

A software solution based on OpenFlow that integrates and orchestrates HRC modules, monitors the execution and responds to shopfloor events to complete a given production goal.

OpenFlow can orchestrate, model and control many diverse state-of-the-art software and software controlled mechatronic systems such as cobots, mobile robots, agvs, AR applications, AI detection and prediction software, as well as sensors, machinery, planning and ERP systems.

The adoption of such integrated platform will allow an augmented flexibility in the production line as well as a high rate of reconfigurability of the platform in a complete collaborative and open environment.

————————————————–

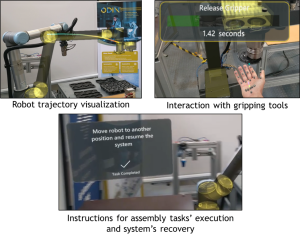

Augmented reality suite assisting operators in Human-Robot Collaborative environments in which resources collaboration is required for different assembly tasks execution. Thanks to its integration with the shopfloor’s Digital Twin and Robotic Operation System (ROS), the AR suite achieves the efficient HRC in multiple aspects namely:

- assembly guidance provision,

- robot controlling,

- interaction with gripping tools,

- safety awareness,

- resilience in case of robot actions failure,

- cyber security and

- quality inspection result awareness.